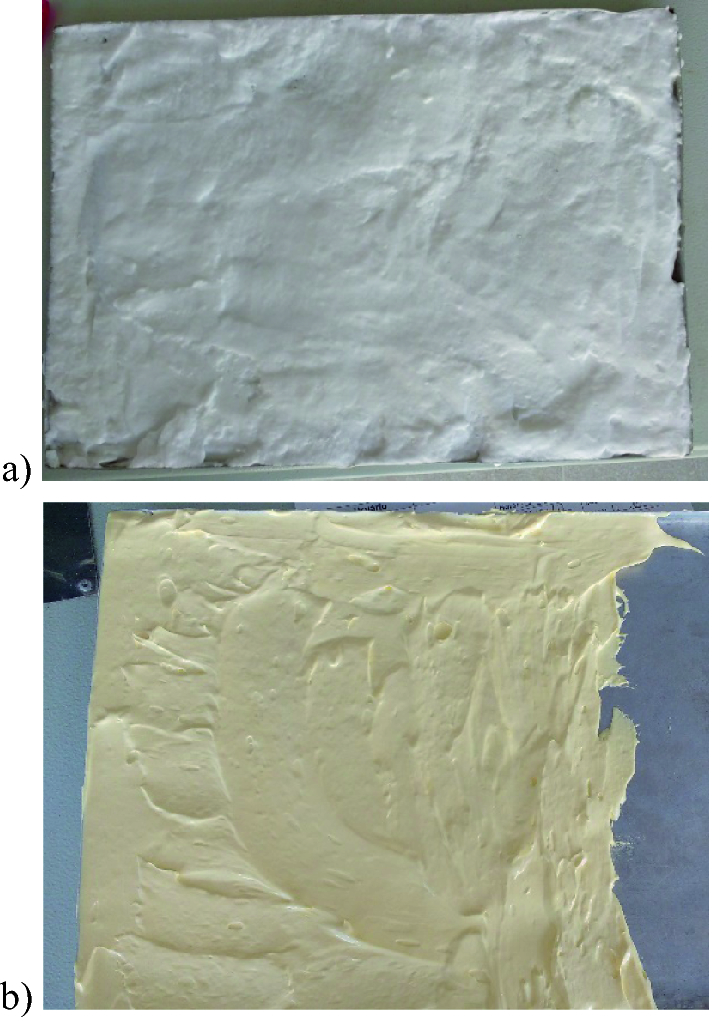

The conversion of seabuckthorn juice pulp into foam was standardized by whipping the pulp after addition of cmc 0 3 at 5 c and drying the resultant foam in dehydrator 55 2 c to a.

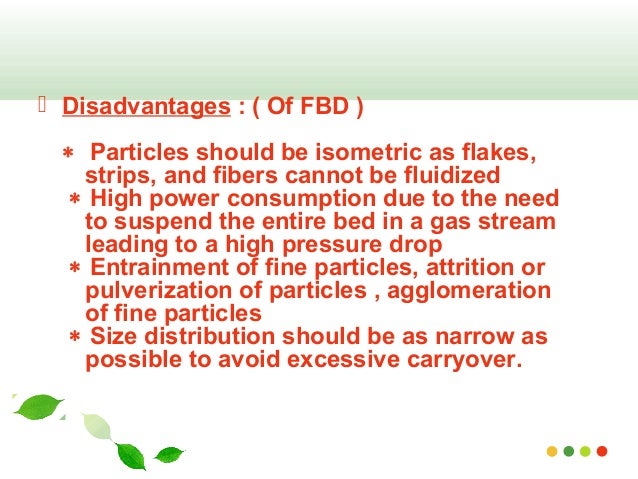

Disadvantages of foam mat drying.

Compared to the other drying methods the rapid removal of water during the foam mat drying is due to three main reasons.

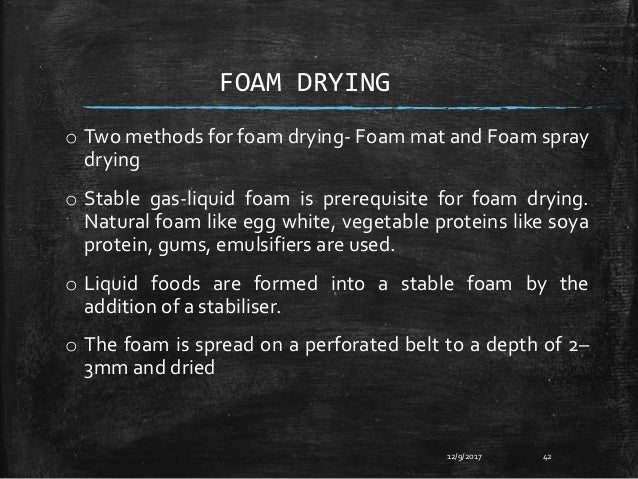

The three basic foam drying variants vacuum puff foam mat and foam spray drying are reviewed.

The memory foam substance relieves pressure prevents fatigue and allows you to stand up longer.

The disadvantages of spray foam insulation have recently come to the forefront with multiple studies and research collected from the environmental protection agency epa which found that when spray polyurethane foam is being used that the worksite or home should be restricted to people who are not wearing appropriate personal protective.

The memory foam mats are also very.

Drying and microwave foam mat drying sangamithra et al 2015a.

Simply put them in the washing machine and they are ready.

The heat sensitive nature of phytochemicals are degraded when exposed to high temperature for prolonged period.

Foam mat drying is therefore a suitable method to dry vegetable juice without degrading phytochemicals and cheaper than vacuum freeze and spray drying methods kadam et al 2010.

The advantages of foam mat drying and ultrasound pretreatment were combined and the effects on the drying behavior and time effective moisture diffusivity physical and powder properties of taro flo.

Foam drying foods is now an established unit operation in the food industry.

A great feature of these mats is that they are easy to car for.

And foam mat drying for fruit and vegetable juices.