Direct metal laser sintering dmls aluminum alsi10mg is traditionally a die casting material characterized by low weight and good thermal properties strength and hardness.

Direct metal laser sintering 3d printer cost.

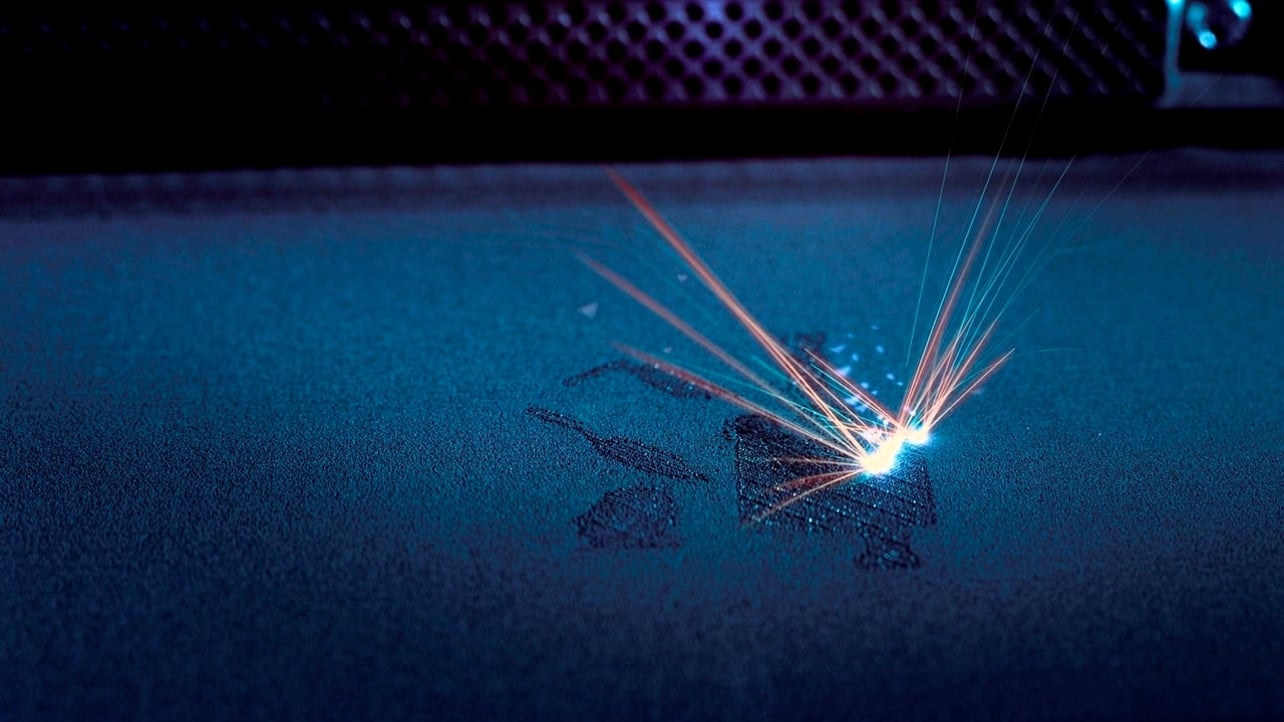

Direct metal laser sintering or dmls is a 3d printing technology that uses lasers to fuse powdered metals into functional prototypes and end use parts.

3d printing isn t just confined to plastic.

Direct metal laser sintering dmls is an industrial metal 3d printing process that builds fully functional metal prototypes and production parts in 7 days or less.

Aluminum alsi10mg makes a good candidate for lower cost dmls prototypes but is also seen in production parts and can be post machined.

Direct metal laser sintering is a groundbreaking metal 3d printing technology.

This powder layer is spread to be the same as the height of one layer usually 20 100 microns.

The print chamber of the 3d printer is then heated up.

Suitable for metal prototypes and functional end use parts and for reducing metal volume in the component.

Protolabs free dmls design guidelines help you assess capabilities and limitations.

A range of metals produce final parts that can be used for end use applications.

Learn all about direct metal laser sintering one of few 3d printing technologies capable of making parts directly from metal.

It can rapidly create metal parts that are more complex and dense than subtractive manufacturing techniques can achieve.

The two are instantiations of the same concept.

Dmls is able to support internal design features that cannot be created by other machining processes allowing for greater design innovation.

Direct metal laser sintering slm 3d printing process.